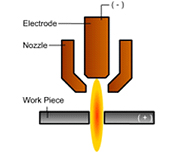

- This process generally uses a single gas (usually air or nitrogen) that both cools and produces the plasma.

- Most of these systems are rated at under 100 Amps, for cutting materials under 5/8" thick.

- Primarily used in hand held applications

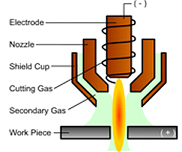

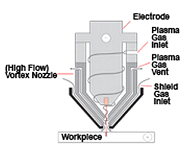

- This process utilizes two gases; one for the plasma and one as a shield gas.

- The shield gas is used to shield the cut area from atmosphere, producing a cleaner cut edge. This is probably the most popular variation, as many different gas combinations can be used to produce the best possible cut quality on a given material.

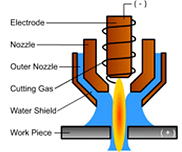

- This is a variation of the dual gas process where water is substituted for the shield gas.

- It produces improved nozzle and workpiece cooling along with better cut quality on stainless steel.

- This process is for mechanized applications only.

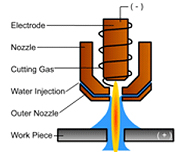

- This process uses a single gas for plasma and utilizes water either radially or swirl injected directly into the arc to greatly improve arc constriction, therefore arc density and temperatures increase.

- This process is used from 260 to 750 amps for high quality cutting of many materials and thicknesses.

- This process is for mechanized applications only.

- This process produces superior cut quality on thinner materials, (less than 1/2") at slower speeds. This improved quality is a result of using the latest technology to super constrict the arc, dramatically increasing energy density.

- The slower speeds are required to allow the motion device to contour more accurately.

- This process is for mechanized applications only.